In a recent presentation by Mark Gjerek, founder of Mov3ment, a consultancy firm dedicated to decarbonising transport, the focus was squarely on the urgent need for energy efficiency in the transport sector, particularly within heavy vehicles like trucks and buses.

Mov3ment specialises in helping organisations understand and adapt to the evolving landscape of transport, with a particular emphasis on reducing environmental impacts and energy consumption. The presentation in the webinar on decarbonising road transport in Australia highlighted key strategies for fleets to significantly reduce their emissions and improve energy productivity.

The challenge: Rising emissions in heavy vehicles

Gjerek began by painting a sobering picture of the current and projected emissions from the heavy vehicle sector. Despite the introduction of zero-emission trucks, emissions from articulated and rigid trucks are set to rise. By 2030, it is expected that around 80% of new trucks sold will still be diesel-powered, and these will constitute approximately 90-95% of all trucks on the road. This reality underscores the need for immediate and significant action to reduce emissions beyond simply waiting for a complete switch to zero-emission vehicles.

Understanding the sources of emissions

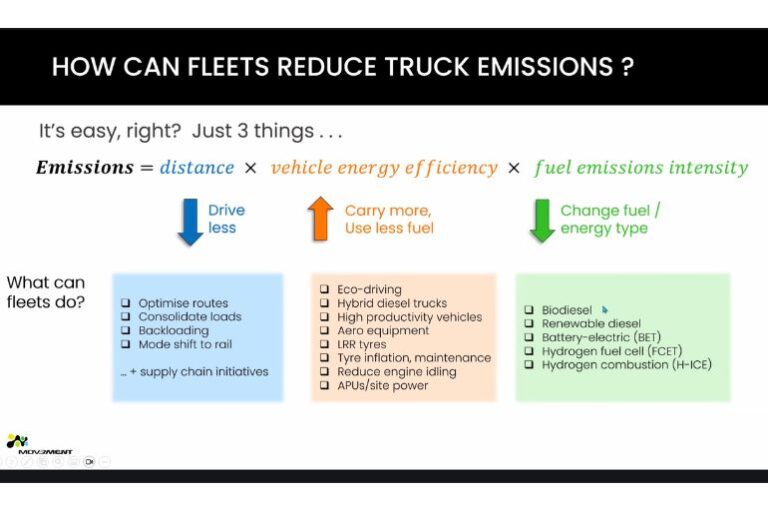

To effectively tackle emissions, it is crucial to understand their sources. Gjerek simplified the emissions equation into three core components: the distance vehicles travel, the energy they use, and the carbon footprint of that energy. Addressing these components involves strategies such as reducing travel distances, increasing load efficiency, and switching to lower-carbon fuels.

However, Gjerek emphasised that for fleets, the focus should not only be on these broad categories but on specific, actionable strategies within them. While fleet operators often shy away from discussions about driving less—since more driving typically means more revenue—there are still opportunities to optimise routes, consolidate loads, and improve backloading.

Energy productivity: The untapped potential

Gjerek’s presentation zeroed in on energy productivity as a critical area where fleets can achieve significant emissions reductions. He outlined various categories of opportunities, each with the potential to contribute to fuel savings and reduced emissions. These categories included:

- Aerodynamics: Optimising the aerodynamics of both trucks and trailers can lead to fuel savings of up to 10%. This includes improvements in trailer design and the use of aerodynamic devices that reduce drag.

- Tyres: As the only point of contact between the truck and the road, tyres play a crucial role in energy efficiency. Choosing low rolling resistance tyres can save around 5% in fuel consumption, though the exact savings can vary depending on the specific application.

- Driveline efficiency: This includes simple measures like turning off the engine when the vehicle is idling, as well as more advanced solutions such as hybrid powertrains. The latter, in particular, represents a significant opportunity for fuel savings.

- Driver dehaviour: Driver training and feedback systems can have a substantial impact on fuel efficiency. Gjerek cited case studies where comprehensive driver training programmes resulted in fuel savings of up to 15%.

- Maintenance: Regular and proactive maintenance can improve the efficiency of a vehicle’s engine and other systems, contributing to overall fuel savings.

Gjerek pointed out that while each of these categories might only offer savings in the range of 5-20%, when combined, they can result in substantial overall savings. Even accounting for the fact that some measures might overlap and reduce each other’s effectiveness slightly, the cumulative effect can still be significant.

The economic argument: Cost-effective emissions reductions

One of the key messages from Gjerek’s presentation was that improving energy efficiency is not just about reducing emissions; it also makes economic sense. Every litre of diesel saved represents a cost saving for fleet operators, many of whom operate on very thin margins. By focusing on low-cost, high-impact measures, fleets can achieve significant emissions reductions without incurring prohibitive costs.

Gjerek highlighted that fuel switching, while potentially offering substantial emissions reductions, can be costly and complex to implement. In contrast, energy productivity measures often require minimal capital investment and can deliver immediate financial benefits. For example, while the impact of driver training on emissions might be relatively modest compared to fuel switching, it is also relatively inexpensive to implement, making it a cost-effective first step for many fleets.

Real-world impact: A case study

To illustrate the real-world potential of these strategies, Gjerek shared a case study of a fleet of 36 trucks operating in local pickup and delivery. This fleet was spending approximately $500,000 per year on diesel. By focusing on three key opportunities—route optimisation, reducing idle time, and investing in hybrid trucks for new contracts—they were able to achieve significant savings.

Over a five-year period, these measures resulted in approximately $180,000 in fuel savings, with a relatively small capital outlay. This example underscores the potential for fleets to achieve both environmental and economic benefits by focusing on energy productivity.

Barriers and solutions: Access to information and resources

Despite the clear benefits, many fleets struggle to access the information and resources needed to implement these energy productivity measures. Gjerek acknowledged this challenge and highlighted efforts to address it. Mov3ment is working with industry organisations like NatRoad, which represents small and medium-sized fleet operators, to develop resources and guidance on fuel savings and emissions reductions. These resources are designed to be practical and accessible, helping fleets navigate the complexities of decarbonisation.

One such initiative involves mapping out the process that fleets should follow to identify and implement energy efficiency measures, supported by detailed guidance at each step. These resources are freely available on the NatRoad website, offering a valuable tool for fleets looking to reduce their emissions.

The path forward for fleets

Gjerek concluded his presentation with a call to action for fleets to take advantage of the opportunities available to them. While the transition to zero-emission vehicles is an important long-term goal, there is a pressing need for immediate action to improve energy productivity and reduce emissions. By focusing on cost-effective measures that deliver both environmental and economic benefits, fleets can play a crucial role in addressing the transport sector’s emissions challenge.

For fleet operators, the message is clear: significant emissions reductions are within reach, and they don’t have to come at the expense of profitability. By embracing energy productivity and making smart, targeted investments, fleets can help solve the freight decarbonisation puzzle—while also improving their bottom line.